“Always deliver more than expected.” – Larry Page

An employer always needs to keep track of his production numbers in order to achieve constant growth and profits. Productivity in the work space is different than managing productivity on the manufacturing floor. The employees operate under different circumstances and pressures and both need to be tackled differently. Increased productivity on the manufacturing floor depends on efficient employees, better equipments and better processes. You may need to enhance your training pattern, equipments and also the system.

At Purshotam Company Private Limited, a leading distributor of metal marking machines in India, we believe it is best to chalk out a baseline first and determine your existing output levels, so that you can implement solutions to increase in productivity. Mentioned below are some crucial steps that can help you design a more productive and efficient manufacturing floor in order to increase productivity:

Examine the Existing Obstacles

In order to come up with a better solution, you need to first pick out the pain points in your current manufacturing system. Analyze the personnel, expertise, technology and raw material being used. Consider using value mapping as an effective solution for process improvement. Chalk out your budget and determine which technologies can do with an upgrade for increased productivity.

Update Business Processes

After determining the possible and obvious obstacles, you need to re-devise your business processes and manufacturing process by taking ideas from project managers and implementing changes wherever needed. This could also entail re-assigning resources to different people, different areas and also to re-plan your budget. You can also consider getting an ISO certificate to improve your floor productivity.

Invest in Employee Education

You may have hired the best technicians or employees for your manufacturing process but technologies and strategies constantly upgrade. For this reason, you need to constantly brain-storm and train your employees with better methods and technologies to make your manufacturing floors more efficient.

Have Realistic Expectations

Do not set the goals to unattainable levels as doing so will not only de-motivate your employees but also make them dissatisfied or compromise on quality. Keep realistic expectations which help to boost worker efficiency and set clearly defined objectives that ensure quality, punctuality and also safety.

Upgrade your Technology

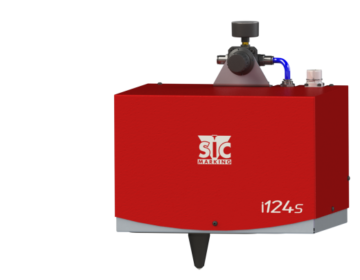

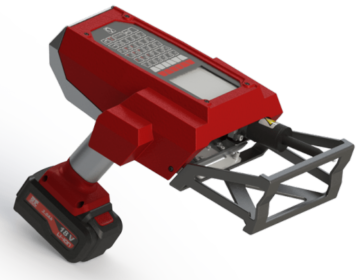

Tools are the most important factors which can help boost productivity. Invest in new machinery and ensure that proper training regarding usage and safety has been given to the employees. This will also help the company stay competitive in the market.

Invest in Maintenance

New equipment can definitely boost productivity, but it also requires periodic maintenance in order to run without any disturbance. Also training employees to troubleshoot their machines can help them find the causes of errors instantly.