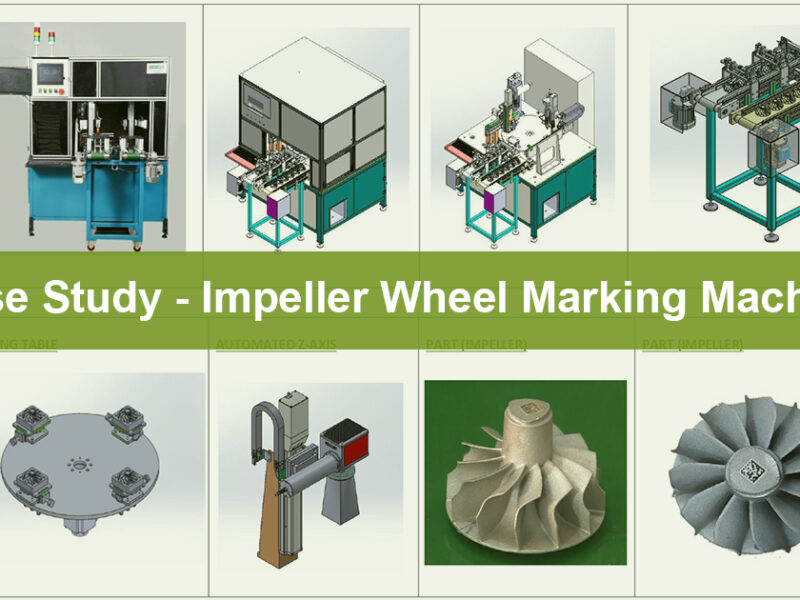

A high speed automated marking station with high accuracy to mark model number and serial

number as a 2D data matrix on 30 different types of impeller wheels. After marking the 2D data

matrix barcode, the grade of barcode needs to be verified and recorded for tracking purpose. And

non-acceptable grade parts are isolated separately without any human intervention.

How it works?

How it works?

Step 1: The operator selects the component model from the Human Machine Interface (HMI).

Step 2: Then the operator will manually place the respective component on the infeed conveyor.

Step 3: Now, the “Pick and Place” mechanism will pick the component from the infeed conveyor and place it on the indexing table.

Step 4: The indexing table will rotate by 90 degrees and take the component to the marking location.

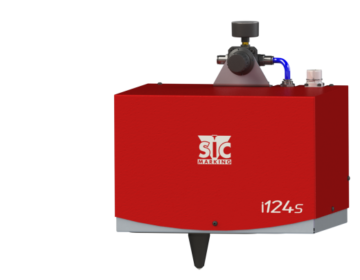

Step 5: Now, the marking machine will start marking.

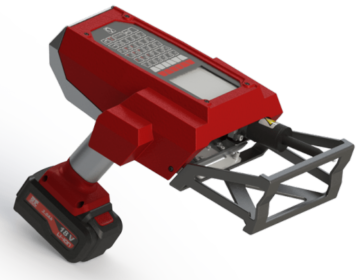

Step 6: Grade verifier is used to compare the data and verify the grades.

Step 7: After verification, accepted components are fed to the outfeed conveyor and rejected components are dropped in rejection bin.