Purshotam Company Private Limited was founded on the premise of providing high quality metal marking solutions to all businesses irrespective of their scale and size. Today, we are proud to say that, we have been successful in giving our clients the right metal marking solution at the right price.

In the previous article of this series, we spoke about the marking technologies that came after dot peen, namely, scribing and laser marking.

Once you have the marking machine, how do you place and position them on the shop-floor to maximize productivity and performance?

Column Mounted Marking Machine

The most commonly used machine for off-production line marking of parts is column mounted machine. Most prominent in this category is the dot peen type marking machine. These machines can mark up to 3,000 parts per day, with an accuracy of 0.02 mm.

They can mark parts of different shapes and surfaces like flat, concave, convex, or circular. Different marking types can be stored as software and can be downloaded from a PC onto the machine’s controller, using USB key.

Linear, angular, radial, and mirror-image marking is also possible. The software also incorporates self-diagnostics and machine-history functions.

Some column mounted machines are laser type as well. These machines are primarily used for direct part marking or label marking, which require greater accuracy. Software is used to steer the laser beam for different types of marking.

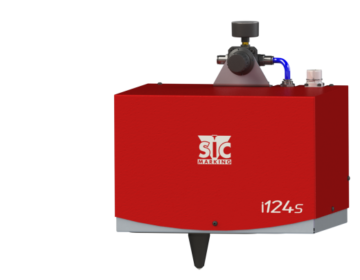

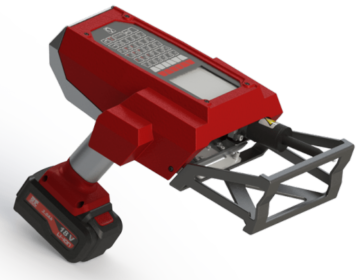

At Purshotam Company Private Limited, we offer a variety of column mounted marking solutions. Here is a quick glimpse into our column mounted marking machines.

E10 C153

Using unique electromagnetic marking technology, the c153 column mounted system can adapt to various shapes and surface conditions, whether flat, concave, convex, circular, or raw. It requires only one source of energy, having a 160 x 100 mm marking window, and LED lighting, it is convenient to use.

E10 C153 ZA

As its name suggests it is a dot peen marking machine with automatic Z-axis, capable of marking on surfaces of plastic and steel (up to 62 HRC).

E10 C303

It is another member of the dot peen marking machine family with similar features but with a larger marking window of 300 X 150 mm and capacity of marking 3000 parts per day with 0.02mm accuracy.

EC1

The ec1 column-mounted dot peen marking system is specially designed for small industries with a limited budget for marking parts. Ideal for marking small to medium sized parts.

In the next part, we discuss other systems of using metal marking machines on the shop-floor. Stay tuned.

To know more about Purshotam, and our offerings, reach out to us now!