Purshotam Company Private Limited was established with an intent to serve the manufacturing industry and meet their tracing and identification needs. Today, we have a pan-India presence and have also partnered with the leading manufacturers of the country, but we are still not satisfied.

We always keep our clients first and want to do more for them. Thus, we offer high-level of customization on our metal marking offerings when standard machines fail to meet the expectation of our patrons.

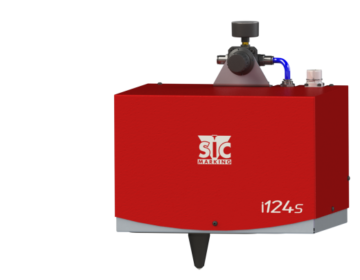

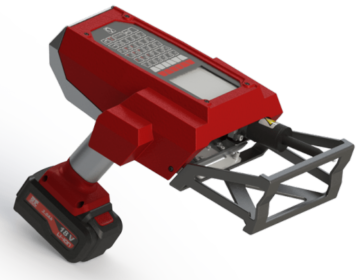

In this series we have already discussed, the birth of marking machines, dot peen marking, scribing, and laser marking. We have also discussed briefly about column mounted, integrated, and portable marking machines. Today we talk about customized marking solutions.

Customization and Innovation

At Purshotam Company Private Limited, we understand that, while in most applications it is possible to simply plug in an integrated marking machine on to the production line or mark large number of parts offline using a column mounted marking machine; there are some applications that need customization.

For instance, to mark a shaft with varying length and diameter at its end, it may need customization in the form of fixtures to hold the shaft in vertical or horizontal position. Surface detection is done using sensors.

Similarly, to mark three different plates of varying sizes will also need customization. Here, plate-feeders of different sizes are made and marking cycles are designed accordingly.

In another example, circular marking on screw heads of different head-diameters is achieved using motorized axis on a pneumatic actuator. Screws are held in place using pneumatic clamping. Motorized axis and pneumatic actuator help in saving marking cycle time.

Customization in integrated marking machine on a production line is also feasible. For instance, laser marking on cylinder heads, bearing caps and cast-aluminium crank cases.

Among innovations, data matrix and automated vision solution is prominent. It is essentially a “mark and check” system which offers an effective traceability system. Here the marking is in the form of data matrix code. To verify the quality and readability of this mark, a vision system using camera is employed. Thereafter verification is done, wherein the data matrix reading is compared with specified parameters or metrics defined by ISO standards. Such a mark and check system ensures that there would be no errors in identification and traceability.

At Purshotam, we take every customization challenge as an opportunity to serve our clients better. We will surely share our success stories with you.

To learn how we can provide you custom metal marking solutions, reach out to us now!