As the manufacturing industry grew, Purshotam Company Private Limited realized that there is a growing need for marking important parts used in assemblies. Thus, we started distributing metal marking solutions to the manufacturing sector.

With time the metal marking technologies changed. Today, we share with you the marking technologies that came after dot peen marking.

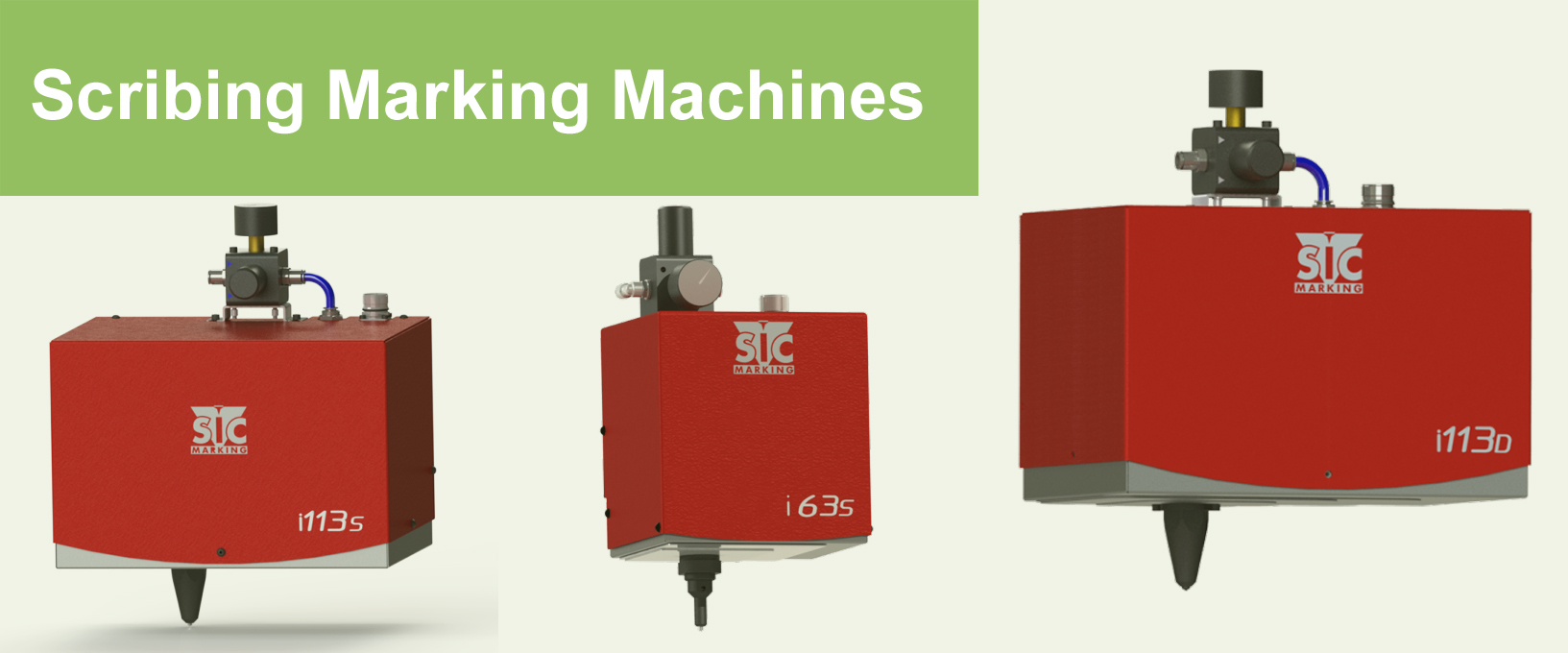

Scribing

In this type of marking, a carbide or diamond tip penetrates the surface and makes a groove. The marking therefore is in the form of a continuous line or a continuous groove. This is also called “drop and drag” or “scratch” marking.

The fundamental advantage of this marking is low-noise operation as compared to dot peen marking. This type of marking works well with optical character recognition. Most of scribing marking machines use pneumatic movement for the marking tip.

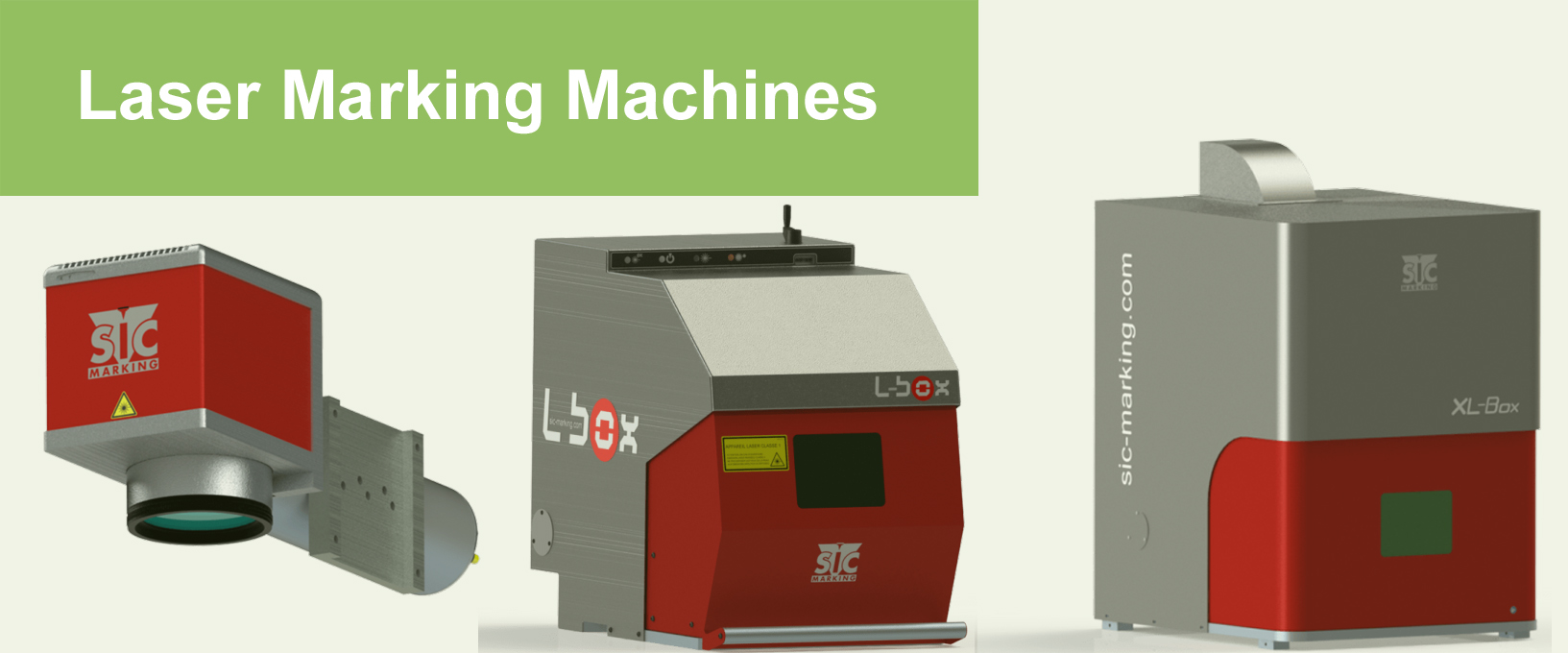

Laser

Laser is a high energy beam of monochromatic light, which can penetrate even metal. For metal marking, a high frequency beam is generated from a laser source and is then amplified in a fibre optic cable, and focused using a series of rotating mirrors. A lens then concentrates this beam into 30 micro meter size.

When this laser beam hits a metal surface, three distinct reactions take place –engraving, annealing, and foaming. While engraving creates a groove, annealing changes material colour at the groove. Foaming alters the coating at the surface. A fibre laser has proved to be a reliable and low maintenance option for marking.

Along with dot peen metal marking machines, Purshotam Company Private Limited also offers a variety of scribing and laser marking solutions to meet your metal marking needs.

Our laser marking solutions have become extremely popular across the industry due to its performance and low maintenance costs.

In the next part of this series, we discuss how these new technologies became a part of the shop-floor and how they improved the marking efficiency and speed.

For more information on Purshotam Company Private Limited and our offerings, reach out to us now.