It is estimated that 98% of the industry uses pneumatic dot peen marking machine. There is also an assumption that since pneumatic machines cannot be controlled with meticulous precision, dot peen marking machines struggle to mark on a surface of 1mm thickness.

Marking need

Well, one day we received a call from a troubled client, who wanted to mark platinum, yes a platinum surface with 0.25 mm thickness!

This was obviously challenging not only because of the thickness but also because of the material. Platinum tends to be more expensive than gold and you do not want to accidently damage or waste some of it while marking.

Marking solution

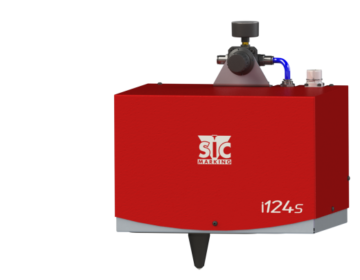

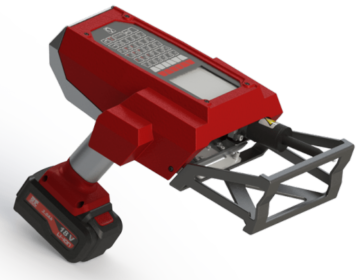

We could not go with a pneumatic dot peen marking machine due to the control and precision issues associated with an air-based machine. We decided to challenge the dominant hold of the pneumatic dot peen marking machines and introduced the electromagnetic dot peen marking machine by SIC Marking.

Client Satisfaction

By using the electromagnetic dot peen marking machine, we were not only able to mark on a platinum surface of 0.25 mm thickness but also have a character size of 0.5 mm/0.5 mm. We owe this to the input control on the electromagnetic marking machine.

In addition to this, the dot peen marking machine that we used had a rack and pinion system, not a belt driven system, which increased accuracy significantly!

Our client was pleasantly surprised and extremely happy that we could give him the output that he wanted.

At Purshotam Company Private Limited, we use our expertise and devotion towards our clients to provide them the right marking solution. Even after all these years of leading the metal marking distribution industry, we still wake up each day thinking of ways to serve our clients better.

Would you like to work with a marking partner who is committed to meet your needs? If yes, contact us now. We will be happy to hear from you.