Purshotam has been serving the Indian industry since pre-independence days. When the Indian industry was at a nascent stage, we made available world-class industrials to improve productivity. We then started to distribute the renowned French SIC Group’s marking machines in India and went on to become the world’s largest distributor of SIC marking machines.

Marking fulfils an important need of the manufacturing industry – namely identification and traceability of mass-produced components. By offering an optimum marking solution to our customers, integrating the marking machine with production lines, and automating the marking process; we were able to enhance shop-floor productivity for all our customers. Thus started another important mission for us, -to enhance productivity. We have gone on to offer automation solutions to customers in furtherance of this mission, and we continue to look for ways to enhance productivity on shop-floor.

Our productivity solutions are distributed over the following 4 main verticals –

- Marking machine solutions

- Shop floor automation

- Autoloader gantry solutions

- Gauging solutions

- Marking Machine Solutions

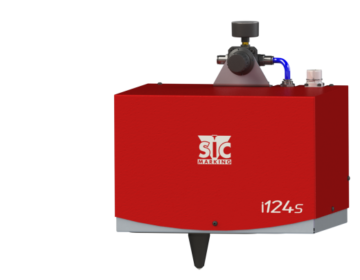

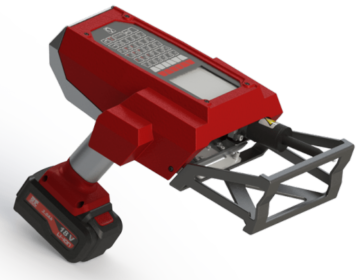

Machine Selection: We offer a wide range of marking machines and always strive to match each customer’s specific requirement with an optimum solution. While column mounted dot-peen machines are the most popular for mass-produced parts, portable dot-peen machines are used for marking large size jobs. These machines are compact, lightweight, and battery operated, which makes them very versatile. These machines can mark on hardened metal up to 62 HRC hardness, and on plastic as well. Subscribing and laser marking machines are also available to be used in a variety of marking applications.

Marking Machine Integration: A range of compact marking machines are available for integration into automatic production lines. These are mostly high speed dot peen machines, with powerful integrated software. These marking machines are robust and reliable, and designed for intense industrial use. Yet, they have low maintenance cost. Subscribing type marking machines are also used for integration with auto production lines, which need low-noise operation. These have diamond stylus which uses engraving type of marking.

Marking Machine Automation : To provide higher marking speed, automation solutions are employed which seek to automate the marking process and significantly reduce the overall cycle time. Dot peen or laser type marking machines are used in automation. Some popular applications are two-wheeler chassis, engine block, crank shaft, engine valve etc. Specially designed fixtures and clamps are used to hold the machine and the part to be marked, and specific sensors are used to detect marking position. Marking machine’s front fascia is customized if necessary to reduce the cycle time.

Key Customer Benefits

- All marking machines are rugged and reliable

- Low maintenance cost, low consumable usage

- Portable machines are autonomous and battery operated

- Good flexibility and variety in marking, controlled by software

- Easy to integrate on production lines, to increase productivity

- Shop Floor Automation

Automation on shop floor is provided with the help of in-feed and out-feed conveyor systems, and loading & unloading of parts, which is normally done with pneumatic cylinders. Different types of conveyors such as belt, roller, and slat type are used depending upon the process.

Special trolleys are also designed for handling of machines and material on the shop floor. We have also designed automated systems for loading and unloading of industrial tiles. These are large size automation projects with total loading capacity of 140 tons and conveyor length of 40 meters. Floor system for storage is also designed as per user requirement.

Key Customer Benefits

- Conveyor system of all sizes and types can be designed at low cost to achieve optimum productivity

- Different type of conveyors like belt, roller, or slat can be offered to match with the requirement

- Long conveyor with high loading capacity can also be offered

- Automation can be provided in different applications such as pin pressing with pneumatic press system, trigger wheel Bolt tightening, con rod tightening with spindle nut runner etc.

- Autoloader Solutions

It is essentially a gantry automation solution for loading/unloading of components on CNC machining centers. It significantly enhances productivity of mass produced components in auto and engineering industry, which require quick loading and unloading. Our “Handler” solution has high precision and can be used to load and unload lightweight components like bearing races, gears, pistons, hydraulic and pneumatic components, fasteners, flanges etc. We provide end to end solutions after studying customer’s process. Our solution includes design, supply of material, erection on ground and commissioning. We provide a range of AMC options too.

Key Customer Benefits

- End to end solution at optimum cost

- Can handle a variety of lightweight components

- Can handle two machines operating on different components

- Provides high productivity in mass-produced components

- Gauging Solutions

We offer a variety of accurate and reliable gauging equipment, using LVDT with digital readout. We provide 1 channel, 2 channel, 4 Channel, and 8 channel LVDT. Column type gauging equipment with one or two channel is also available. Main features of these gauging equipment are :

- High resolution, reading as low as 0.1 micro meter

- Measurement modes –current, minimum, maximum, and differential

- Indication for reject, ok, rework

- Auto calibration is provided

- User interface RS 232, RS 485, Ethernet, and USB 2.0

Key Customer Benefits

- A wide variety of gauging equipment to choose from. From 1 channel LVDT, to 2, 4, and 8 channel LVDT with digital read out

- Output can be interfaced with PC or similar devices

- Column type display also available

- Gauging equipment integrated with customer production process to improve productivity

- Indications of reject, ok, rework

- Variety of interfaces available including USB 2.0 for PC

- In 8 channel LVDT, micro SD card is provided for data storage. Also, result formula can be edited by the user.