Marking systems are used for the permanent part identification purpose for various industries. Today, the foremost effective marking system that’s accessible within the market is ‘Metal Marking Machine”. It’s one amongst the quick marking machines accessible and it will be used even with hardest metals also. The quality assured by Metal Marking is comparatively very high. High accuracy metal marking tiny things achieves speedy originated. It minimizes waste and will increase outturn. Metal marking is used in dynamic, highly adaptable process for a high-speed character, logo, graphics, barcode and two-dimensional data matrix marking. In addition to that, metal marking is highly readable and permanent and it discourages tampering. And moreover, they are able to withstand in harsh environmental conditions.

However, some may be under the impression that most marking machines are only able to mark alphanumeric text on a metal plate or tag; but, there are many types of machines that have the ability to produce logos, images, and machine-readable barcodes on a metal plate or tag, mainly for part marking and product traceability purposes.

Metal marking machine is dot matrix machine that can mark letters, numbers, and images, along with a 2D data matrix barcode on a metal plate or tag. The main benefit of marking a metal tag with a 2D data matrix barcode is to identify a part or a product with more extensive information than a standard barcode can hold and for capturing the data electronically. Industries that work with electronic tracking and traceability systems need a solution that will produce a permanent mark on a metal plate or tag able to hold the information associated with that specific part, equipment, product, etc.

This machine is automatic and can run off of a database or information can be entered manually. It contains a hopper which holds the plates and feeds them onto a small platform where the plate is secured and the marking takes place. Once the information is marked on the plate, it is then moved to the right and either stacked in the output hopper or ejected out the side eject area.

This machine is different from our other machines in that it is not an embosser by definition; it is actually more similar to a laser engraver. It marks metal plates by way of a sequence of tiny raised dots, as opposed to embossed alphanumeric characters, and therefore has the ability to mark virtually anything you desire, including a 2d data matrix barcode, letters, numbers, symbols, logos, and graphics. Here are some of the major types of metal marking machine options:

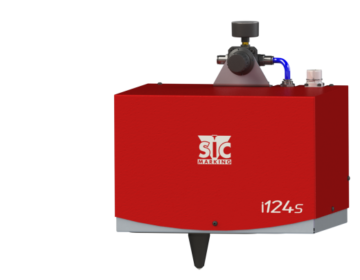

Column Mounted Marking Machine

Column mounted marking machines are extremely flexible and can easily be adapted to a wide variety of component, shape, and dimension. Height position is adjustable either manually or with an automatic digital Z axis. This product line ranges from medium production to 24/7 capable systems.

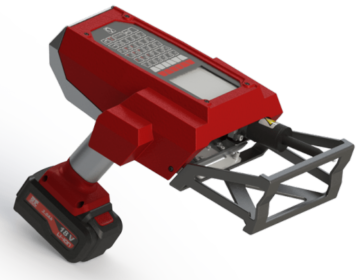

Portable Marking Machine

Today, Portable dot peen marking machine is automated with marking process for mistake-proof product identification. Safe and easy for operators to use, these hand-held marking systems create deep marks in metals and other surfaces for lasting product identification.

Scribing Marking Machine

Scribing technology generates high-quality continuous line marking with very low noise level operations. Heavy-duty models are perfectly well suited to Vehicle Identification Marking – VIN marking – with deep and reliable indent permanent marks.

Integrated Marking Machine

It is the most advanced dot peen marking systems for factory automation environments, making integration of automatic marking fast and easy for machine builders and OEMs.

Laser Marking Machines

Laser marking is a method widely used for the identification process in all manufacturing industries. This method of marking allows you to simply make marking or identification sign on both soft and hard metal surfaces.

Laser marking is a technology used to label or mark a wide range of materials using a laser beam. Laser beam marking is a convenient method of marking using laser technology has become the mainspring for marking and design purpose in every engineering and manufacturing industry. Many manufacturing companies want to make their brand name or the information that the particular product which they were produced from. Marking with laser beams on printed circuit boards is a competitive process that many industries need to print a special mark or a serial number of their products on circuit boards, chips, etc for traceability.

There are many methods of marking metal plates and tags for product identification and traceability. It really depends on what you are marking, where you are marking, what environment it will be in, and what type of tracking device or method you intend to use that will determine the type of marking machine that is most suitable for you.

Purshotam Company Private Limited, located in Pune, Maharashtra manufactures metal marking machines for identification purposes.